Overview

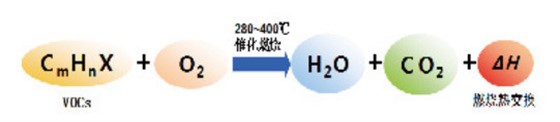

Under the action of the catalyst, the active ingredient of the catalyst can convert the organic matter into CO2 and H2O at a relatively low temperature (280~320℃) and a short time (0.1~0.2s), forming a flameless combustion.

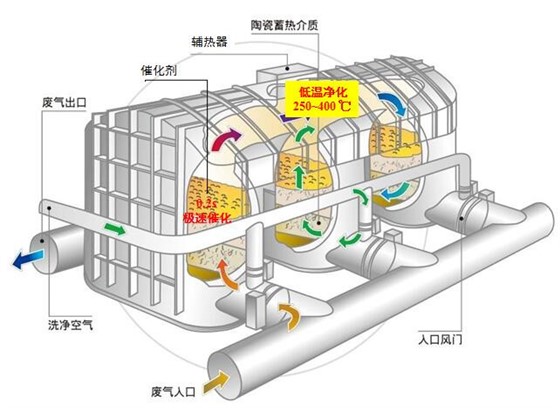

hermal storage catalytic oxidation technology is a non-stationary operation technology developed on the basis of traditional catalytic oxidation method. It is a new technology that integrates two separate processes of catalytic combustion and waste gas preheating in traditional catalytic combustion technology. Equipment integration, high heat recovery, natural operating fuel concentration is low, so there is no need to supplement combustion under the condition of fuel concentration as low as about 1000mg/m3, which can greatly reduce operating costs. At higher concentrations, part of the heat can be removed from it to produce by-product steam for production.

Working principle

Usually VOCs complete oxidation (direct combustion or thermal combustion) requires a higher temperature and a longer residence time, taking benzene as an example, if there is no catalyst, in order to achieve the purpose of complete oxidation, the temperature needs to be above 800 ° C, the tangent residence time of at least 1~2s, with the participation of the catalyst, the complete oxidation temperature and residence time decreased significantly. Only 250~400℃ and 0.1~0.2s are needed, which fully shows the superiority of catalytic combustion method.

Features

1. Low operating costs, no need to consume a lot of electricity or gas, saving operating costs;

2. No secondary pollutants such as nitrogen oxides (NOx);

3. Low investment; Fully automatic control, ready to use; Resistant to impact load, not easily affected by pollutant concentration and temperature changes;

4. High efficiency heat recovery, heat recovery ≧95%;

5. High safety, purification efficiency of more than 98%.

6. The catalyst has high catalytic effect, improves purification efficiency, and reduces input and operating costs.

Application industry

Petroleum, chemical industry, painting, painting, furniture, wire and cable, injection molding, printing, rubber, electronics and integrated circuits and other high-concentration organic waste gas industry.

Specification and parameter table

| Type number |

Processing flow (m3/h) |

Equipment size (mm) |

Heat transfer area (m2) |

Heating power (kw) |

| CRCO-005 | 500 | 2130×1025×1930 | 12 | 33 |

| CRCO-010 | 1000 | 2130×1025×2550 | 24 | 40 |

| CRCO-020 | 2000 | 2230×1175×2560 | 48 | 72 |

| CRCO-030 | 3000 | 2665×1175×2560 | 72 | 90 |

| CRCO-050 | 30000 | 3165×1280×2860 | 120 | 110 |

| CRCO-100 | 10000 | 3865×1360×3060 | 180 | 132 |

| CRCO-200 | 20000 | 4200×1850×3560 | 320 | 196 |

Email:

Email:

Whatsapp:

Whatsapp: