We provide comprehensive services to industrial plants around the world,

focusing on the design and treatment of exhaust gas systems to address issues with acidic, chemical, and other waste gases in production lines.

Our services include manufacturing, installation, commissioning, and testing, along with system training for users to ensure smooth handover.

-------------------------------------------------------

#17+ years of experience in each industry

#Design, manufacture and installation according to customer requirements.

#A team of engineers takes care of every step from beginning to end.

#1-year warranty and lifetime free consultation.

#Designed in accordance with ASME RTP-1 standard and manufactured in accordance with ASTM 3299D standard.

-------------------------------------------------------

#

Email: jschaori@gmail.com

WhatsApp: 19714819527

![]() For more information about wet scrubber 、industrial dust collectors 、Activated Carbon Filter、Silane Burning Towers and Regenerative Thermal Oxidizer. , Please contact us for a free quote through one of the channels below:

For more information about wet scrubber 、industrial dust collectors 、Activated Carbon Filter、Silane Burning Towers and Regenerative Thermal Oxidizer. , Please contact us for a free quote through one of the channels below:

Company Profile

Overview

DGS-B-type fiberglass Industrial wet scrubbers is the company under foreign gas processing equipment and processing company based on the mist of a new generation of acid mist treatment equipment to improve the resistance of the device small, the energy province, low noise, high efficiency . Can handle hydrofluoric acid (HF), hydrochloric acid mist (HCL), sulfuric acid mist (H2SO4), chromic acid mist (CrO3), hydrogen cyanide (HCF), hydrogen sulfide (H2S), ammonia (NH3), alkali vapor ( NaOH) formalin (HCHO) and other acid-alkali water-soluble mixture of gas and gas. After several years of using it, purified exhaust emission standards to Shanghai, below the national emission standards GB16279-1996 "Integrated emission standard of air pollution."

Exhaust gas treatment performance table

| ingredient | concentrationmg/m3 | Purification efficiency% | Neutralizing and absorbing solution |

| HNO3 | ≤200 | ≥95 | 2~7%NaOH liquor and 3-4%Na2S liquor |

| NOX | ≤2000 | ≥95 | 7%NaOH liquor and 3-4%Na2S liquor |

| HF | ≤400 | ≥95 | 2~7%NaOH liquor |

| HCl | ≤400 | ≥98 | 2~7%NaOH liquor |

| H2SO4 | ≤400 | ≥95 | 2~7%NaOH liquor |

| NH3 | ≤4000 | ≥99 | water solution or 2~7%NaOH liquor |

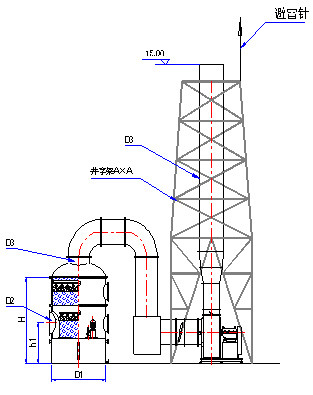

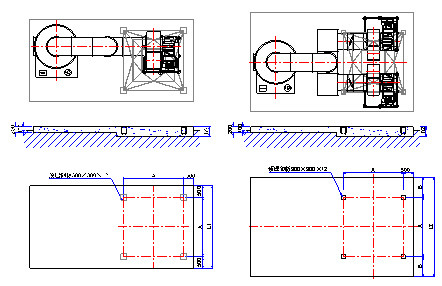

Installation size and foundation

Process principle of industrial waste gaswet scrubbers

Under the action of the fan, the exhaust gas reaches the bottom packing bed, enters the pressure balancing room formed by the internal and external jacket at a low speed, and is transported by circulating pump and washed countercurrent. The exhaust gas is evenly distributed around the PP Terary barbed garland +PP multi-sided hollow ball alternating packing layer, each showing point contact, arranging "Z or W" irregular route walking, without bias phenomenon. Then with the spiral high flow, not blocking the nozzle, so that the gas-liquid two-phase mixing rate of more than 97%, so that the exhaust gas to get the gas-liquid two-phase full contact reaction, and then through the deliquid defogging, to meet the national GB16297-1996 "comprehensive emission standards for air pollutants" in the secondary emission requirements, and finally through the exhaust pipe into the atmosphere.

Packing & Delivery

Email:

Email:

Whatsapp:

Whatsapp: